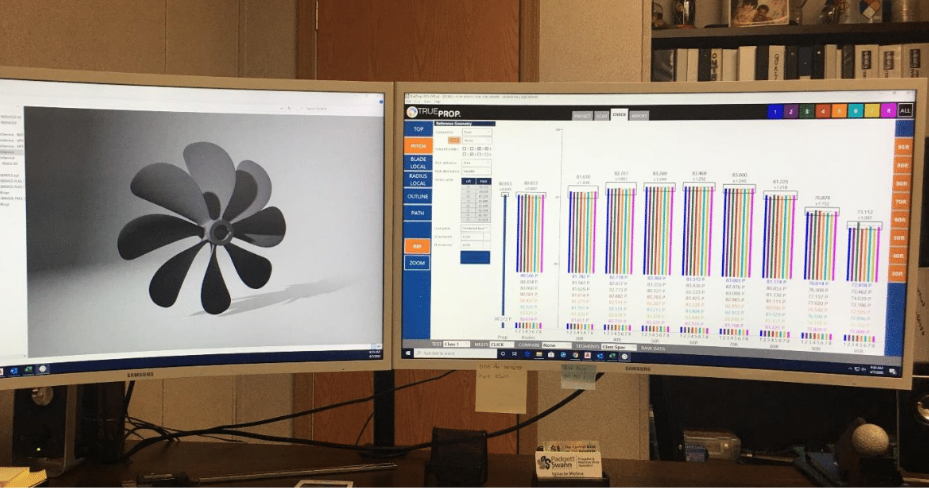

TrueProp for 3D Scanners

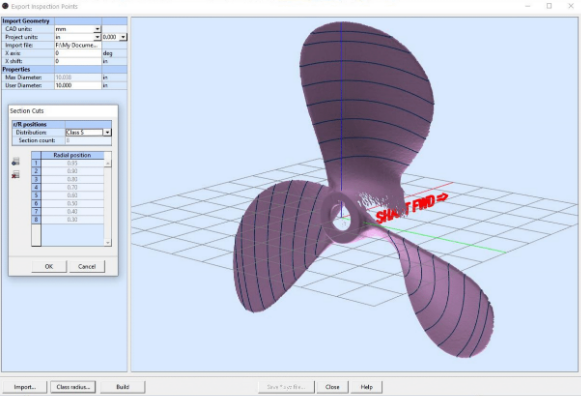

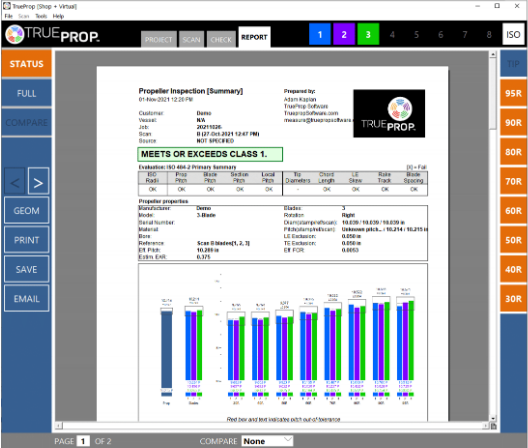

3D scanning systems are a viable replacement for digital pitchometers. The Virtual Import Plugin allows you to extract angle-drop data automatically. This data is then analyzed for Class compliance with TrueProp.

“TrueProp has always been a core component of our propeller repair shop. The information it provides about the propeller helps us to quickly and reliably identify the defects and correct them. In 2024, we incorporated a metrology 3D scanner in our workflow, enabling us to scan propellers directly on the boat and grasp insights that were not possible before. The Virtual Plugin covers the missing gap between the STL output of the scanner and the radius that the ISO standard defines.”

- Alex Roig, Nautic Center

- Alex Roig, Nautic Center

Advantages

- Analyze your 3D scan using industry-standard tolerances (no more color maps!)

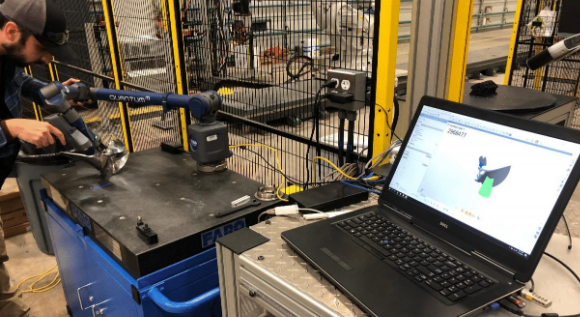

- Propellers can be scanned in any position, including on the vessel

- Scanning systems are portable

- TrueProp can support any 3D scanner

- Eliminates multiple arbors, chucks, and cones for different propeller bores

- Many scanners have no restrictions on diameter, pitch, or blade overlap

- Multi-purpose technology (great for struts and rudders, too)

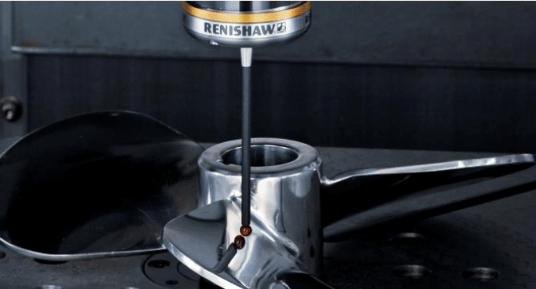

Technologies

|

|

Virtual Inspection Process

|

CAPTURE |

|

EXPORT |

|

Stereolithography files are industry-standard output from most (if not all) 3D scanners. These files recreate the geometry in small triangular patches. The files are very simple and the most basic level output by 3D scanner software. Traditionally, they are hard to work with but TrueProp makes it easy! In fact, TrueProp’s proprietary technology supports partial scans and scans with holes and cracks.

|

|

EXTRACT |

|

ANALYZE |

|

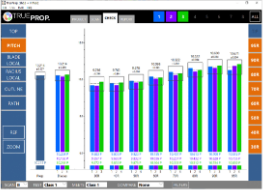

The data is brought into your current TrueProp project, allowing you to document the customer, manufacturer and model. The differences between each blade are reported based on the desired Class tolerance. This allows operators to analyze their 3D scan using the same quality measurements and visualizations required for propeller inspection and repair.

|

|

REPORT |

Learn about TrueProp for Shipyards

An Inside Look: Virtual Propeller Inspection - 3D Laser Scanning

|

|

Get TrueProp and the Virtual Plugin Today! Learn more about our Virtual Bundle!

For more information, contact our sales team at [email protected].

For more information, contact our sales team at [email protected].