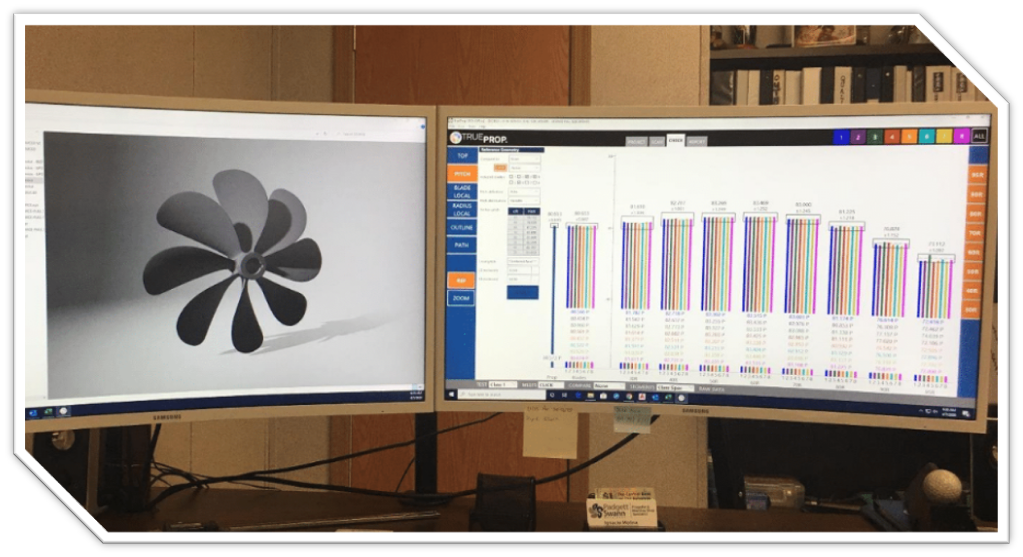

TrueProp for Shipyards

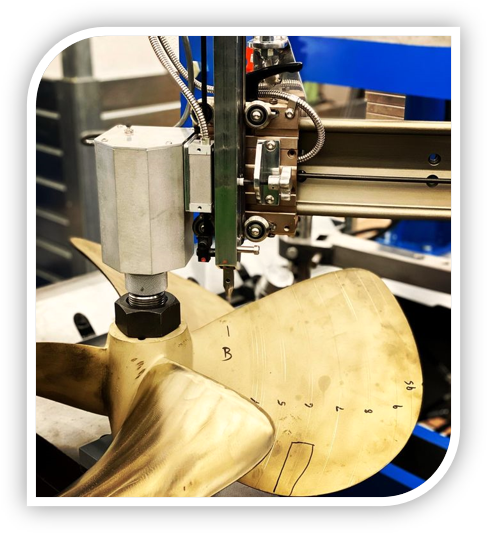

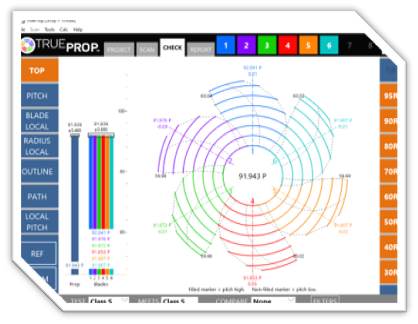

Ship propellers are an absolutely critical maintenance item for ship operators, shipyards, and repair facilities. Damage occurs from many different sources, including groundings, strikes, ingestion of debris, cavitation erosion from high thrust conditions, galvanic corrosion from failed protection systems, and other unpleasant phenomena. TrueProp is here to revolutionize the way shipyards inspect propellers.

When to Inspect

|

Besides the obvious answer (immediately after a grounding or strike), it’s best to inspect the propeller any time the vessel is in the dry dock and accessible. Documenting the condition of the propeller is very useful, even if the vessel is running well. This provides a basis to restore the propeller in case of damage in the future. Having accurate propeller measurements also aids in the selection and sourcing of a replacement propeller.

|

In-Situ Propeller Inspection |

|

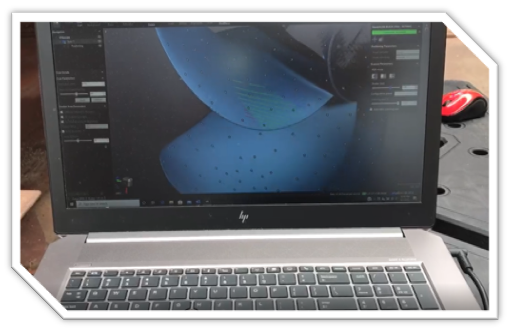

Propellers can be inspected at the yard or in the dry dock. 3D scanning allows propeller inspection without removal. The Virtual Plug-in for TrueProp enables users to process 3D scans files from commercial laser scanning equipment, allowing you to inspect propellers almost anywhere!

|

|

Learn more about our TrueProp Virtual Bundle!

|

|