New Hampshire-based TrueProp was formed in 2017 as an offshoot of HydroComp. Since then, the company’s specialist propeller inspection and repair software has been widely used within the industry. This software has recently been upgraded to meet the evolving requirements of shipyards and other propeller service providers, and now offers a virtual plug-in for 3D scanners.

The TrueProp core product based on inspection and repair codes with a diagnostic screen, remains the same. However, a new parallel code, that enables the software to integrate with a 3D scanner, has been introduced. The TrueProp Virtual Plug-in allows the user to extract angle-drop data automatically. This data is then analysed for class compliance with TrueProp.

This development means there is no longer a need to remove the propeller from the ship, which significantly saves on costs and time for yards. “Our aim is to allow shipyards and drydocks to inspect the propeller without the need for a specialist workshop. The link between our software and the 3D scanner means that yards can inspect even large and complex propellers, including CPP units, with a simple handheld device,” says Adam Kaplan, chief technical officer.

“As a result of this initiative, yards can save a lot of time and money as it is possible to scan the propeller without dismantling and transporting it away from the ship, and to assess if a repair is needed, and if so what type of repair is required, in situ. Consequently, the whole drydocking schedule can be significantly accelerated," adds Kaplan.

According to Kaplan, the new 3D Virtual Plug-in will allow TrueProp to target an expanded market base.“ Whereas previously customers used to have to have specialist machines, and dedicated propeller repair and service workshops, that is no longer the case. This upgrade enables our customer base to be expanded and thereby make the servicing and repair of propeller units more widely available,” he says.

3D scanners are largely general-purpose tools and can be used for a variety of other tasks within a yard, for example in connection with the routing of piping. So, any investment in the device can be quickly paid off. Furthermore, the TrueProp 3D Virtual Plug-in can be used with a variety of commercially available scanners.

The TrueProp core product based on inspection and repair codes with a diagnostic screen, remains the same. However, a new parallel code, that enables the software to integrate with a 3D scanner, has been introduced. The TrueProp Virtual Plug-in allows the user to extract angle-drop data automatically. This data is then analysed for class compliance with TrueProp.

This development means there is no longer a need to remove the propeller from the ship, which significantly saves on costs and time for yards. “Our aim is to allow shipyards and drydocks to inspect the propeller without the need for a specialist workshop. The link between our software and the 3D scanner means that yards can inspect even large and complex propellers, including CPP units, with a simple handheld device,” says Adam Kaplan, chief technical officer.

“As a result of this initiative, yards can save a lot of time and money as it is possible to scan the propeller without dismantling and transporting it away from the ship, and to assess if a repair is needed, and if so what type of repair is required, in situ. Consequently, the whole drydocking schedule can be significantly accelerated," adds Kaplan.

According to Kaplan, the new 3D Virtual Plug-in will allow TrueProp to target an expanded market base.“ Whereas previously customers used to have to have specialist machines, and dedicated propeller repair and service workshops, that is no longer the case. This upgrade enables our customer base to be expanded and thereby make the servicing and repair of propeller units more widely available,” he says.

3D scanners are largely general-purpose tools and can be used for a variety of other tasks within a yard, for example in connection with the routing of piping. So, any investment in the device can be quickly paid off. Furthermore, the TrueProp 3D Virtual Plug-in can be used with a variety of commercially available scanners.

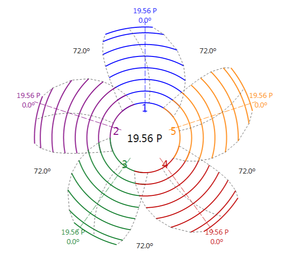

However, the company offers a hardware and software bundle that includes TrueProp Virtual and the Einscan HX from Shining 3D. This bundle allows propellers as large as 3m (120inches) to be scanned with a portable hand-held scanner. The user can enter the diameter and select the radial positions for extracting ISO 484 type data, with a process that mimics the traditional pitchometer process, etching scan lines into the captured propeller in 3D.

The TrueProp Virtual Einscan HX bundle provides fast 3D capture from 14 simultaneous blue light laser lines and its stereolithography (STL) 3D file output is considered perfect for analysis with the TrueProp Virtual edition. “Using the TrueProp Virtual Plug-in, even non-watertight STL meshes can be interrogated at the ISO 484 radial positions. This provides us with the pitch, chord lengths, blade outline and other metrics used in TrueProp’s Class reports,” says Kaplan.

TrueProp Virtual is currently being utilized by more than 30 propeller shops worldwide. The company also reports a significant amount of interest amongst larger shipyards which have traditionally outsourced both propeller inspection and repair. “We are seeing more shipyard interest and at a recent ship repair conference in New Orleans my presentation on the subject attracted a full room! I think that shows that the concept is resonating positively amongst yard operators as well as other propeller service providers," notes Kaplan.

Earlier this year TrueProp 2023 was released as the latest version of the propeller inspection software. The new features include expanded diagnostics to identify and correct damage to propellers, including evaluation of propeller blade thickness, blade areas and effective pitch. Operators can quickly determine what is wrong with a propeller and take corrective action, if necessary, the company states.

With the 2023 version TrueProp has also introduced a new upgrade and support programme. This is claimed to provide much needed support for the propeller service industry, reducing downtime for propeller inspection devices and ensuring that technical questions are answered promptly by other knowledgeable professionals.

The TrueProp Virtual Einscan HX bundle provides fast 3D capture from 14 simultaneous blue light laser lines and its stereolithography (STL) 3D file output is considered perfect for analysis with the TrueProp Virtual edition. “Using the TrueProp Virtual Plug-in, even non-watertight STL meshes can be interrogated at the ISO 484 radial positions. This provides us with the pitch, chord lengths, blade outline and other metrics used in TrueProp’s Class reports,” says Kaplan.

TrueProp Virtual is currently being utilized by more than 30 propeller shops worldwide. The company also reports a significant amount of interest amongst larger shipyards which have traditionally outsourced both propeller inspection and repair. “We are seeing more shipyard interest and at a recent ship repair conference in New Orleans my presentation on the subject attracted a full room! I think that shows that the concept is resonating positively amongst yard operators as well as other propeller service providers," notes Kaplan.

Earlier this year TrueProp 2023 was released as the latest version of the propeller inspection software. The new features include expanded diagnostics to identify and correct damage to propellers, including evaluation of propeller blade thickness, blade areas and effective pitch. Operators can quickly determine what is wrong with a propeller and take corrective action, if necessary, the company states.

With the 2023 version TrueProp has also introduced a new upgrade and support programme. This is claimed to provide much needed support for the propeller service industry, reducing downtime for propeller inspection devices and ensuring that technical questions are answered promptly by other knowledgeable professionals.