Cool Breeze Marine - The Prop Specialists, has been operating for twenty-six years in Osage Beach, Missouri, and is the only certified propeller repair shop in the Lake of the Ozarks. They serve all the United States and several other countries. What does all this attention mean for owners George and Dorothy Peter, on a day-to-day basis?

“Chaos from the second we open our eyes,” says George. “Things get thrown at us constantly.”

Upon finishing college, George became a marine mechanic. After working in this field for a while, he noticed his affinity for propellers. George would visit propeller shops and realized he was better equipped to answer repair questions than the supposed experts. There was a local demand for propeller repair knowledge, since many of the lake’s mechanics and marinas were not tooled or equipped to work on propellers. When a propeller business went up for sale in 1992, George jumped at the opportunity.

Since the 1992 acquisition, George and Dorothy have been very successful. In fact, this year, George had to stop working on boats altogether due to the demand for propeller repair for Cool Breeze - The Prop Specialists. Recently, Cool Breeze acquired a new propeller scanning device and the PropPress 360, a Digital Data Scanner and a hydraulic propeller bending machine from Linden Propellers (Dubuque, Iowa), which together with the new TrueProp Software (Durham, NH) led them to achieve more precise measurements. The Peters are fervent supporters of the combined technology.

“TrueProp, partnered with the Linden DDS and the PropPress 360, is the most accurate system on the market,” says George.

TrueProp is the only independent and widely compatible software available for propeller inspection and repair and makes it easier for people like Dorothy and George to do their jobs. Before Cool Breeze incorporated TrueProp Software, they used manual methods to assess and repair their propellers.

“Chaos from the second we open our eyes,” says George. “Things get thrown at us constantly.”

Upon finishing college, George became a marine mechanic. After working in this field for a while, he noticed his affinity for propellers. George would visit propeller shops and realized he was better equipped to answer repair questions than the supposed experts. There was a local demand for propeller repair knowledge, since many of the lake’s mechanics and marinas were not tooled or equipped to work on propellers. When a propeller business went up for sale in 1992, George jumped at the opportunity.

Since the 1992 acquisition, George and Dorothy have been very successful. In fact, this year, George had to stop working on boats altogether due to the demand for propeller repair for Cool Breeze - The Prop Specialists. Recently, Cool Breeze acquired a new propeller scanning device and the PropPress 360, a Digital Data Scanner and a hydraulic propeller bending machine from Linden Propellers (Dubuque, Iowa), which together with the new TrueProp Software (Durham, NH) led them to achieve more precise measurements. The Peters are fervent supporters of the combined technology.

“TrueProp, partnered with the Linden DDS and the PropPress 360, is the most accurate system on the market,” says George.

TrueProp is the only independent and widely compatible software available for propeller inspection and repair and makes it easier for people like Dorothy and George to do their jobs. Before Cool Breeze incorporated TrueProp Software, they used manual methods to assess and repair their propellers.

“We cleaned the prop a bit, assessed whether it was repairable with manual gauges, and beat the propeller with rawhide or brass hammers to get it to lay on a pitch block,” says Dorothy.

“Then we beat it to the block with heat if necessary. We would weld the missing parts and grind it back to the appropriate thickness and shape, finish them, check and recheck, balance and ship. But we would never really know if it was 100% correct, how could we?”

George adds that heating and hammering the propeller would leave dents and marks and ruined its temper. “Anyway,” he says. “We’re all getting old. Our days of swinging around the sledgehammer are limited, the hydraulics save us from that. No heat is used to bend our propellers. The only heat the propeller sees is from the TIG welder.”

“Then we beat it to the block with heat if necessary. We would weld the missing parts and grind it back to the appropriate thickness and shape, finish them, check and recheck, balance and ship. But we would never really know if it was 100% correct, how could we?”

George adds that heating and hammering the propeller would leave dents and marks and ruined its temper. “Anyway,” he says. “We’re all getting old. Our days of swinging around the sledgehammer are limited, the hydraulics save us from that. No heat is used to bend our propellers. The only heat the propeller sees is from the TIG welder.”

Now Cool Breeze can offer accurate repair to the highest standards available in the industry. “We can show our customers what was wrong with their prop, and then show them how it has been corrected. We are now having larger propellers shipped to us from all over the United States to repair.”

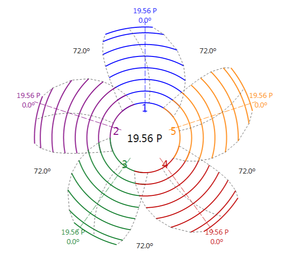

| Cool Breeze customers are excited about TrueProp Software’s printed reports with their colorful and visually appealing charts. “People want a picture of their propellers in their wallet along with their kids’ school photos,” says George. He explains that the Lake of the Ozarks has not been a hub for technology. “It’s several years behind the times,” he laughs. “Not too long ago, our McDonald’s closed during the wintertime.” Before Cool Breeze used the new TrueProp Software, boatowners in the region frequently had to send their propellers to Florida to be repaired, which could take up to a month. Then there was the added expense of transportation. Instead of relying on distant propeller shops with older inspection devices, Cool Breeze decided to bring the complete scan and repair process in-house. |

The arrival of the new technology at the lake has changed everything. “We have the ability to prove that the work was done right,” says Dorothy. “Customers have complete confidence in us. Big props that used to go to Florida now come to us.

"You can’t lie to TrueProp, and TrueProp doesn’t lie to you.”

Since the acquisition of the new PropPress 360 and Linden DDS system with TrueProp Software, the everyday business routine at Cool Breeze may still be chaos, but it is easier to manage. It is catalogued chaos, held together in part by numbers and reports, technology and precision. There is no more need for guesswork, since TrueProp always gives them the best, the truest, results.

Download the article, here.

"You can’t lie to TrueProp, and TrueProp doesn’t lie to you.”

Since the acquisition of the new PropPress 360 and Linden DDS system with TrueProp Software, the everyday business routine at Cool Breeze may still be chaos, but it is easier to manage. It is catalogued chaos, held together in part by numbers and reports, technology and precision. There is no more need for guesswork, since TrueProp always gives them the best, the truest, results.

Download the article, here.

Check out TrueProp Software in action at Cool Breeze Marine! | |