The Leading Edge is a members-only publication from the National Marine Propeller Association. The NMPA is the largest professional society for propeller manufacturers, repair shops, and propulsion equipment vendors. TrueProp is proud to be a contributing member of the NMPA!

Durham, NH – Adam Kaplan, CTO TrueProp Software

If you attended the NMPA Convention this past November, perhaps you saw the panel discussion on repairing new propeller designs. Although many popular designs still use a flat-face, the industry has seen a notable increase in new, contemporary propeller designs such as Veem’s Sportfish and Michigan’s Marlin props. These propellers are deliberately designed for high performance and feature unique geometries that manufactured by CNC machining.

If you measure one of these new propellers, you are likely to notice that the local pitch varies across the blade surface. Let’s quickly review some of these variations…

First, let’s review the propeller from the root to the blade tip. On a traditional propeller, we would expect that the section pitch to be the same at all radii – this is referred to as constant pitch. For example, on a 20 inch pitch propeller with constant pitch, the 50R, 70R, and 90R all measure to 20 inches pitch.

If you attended the NMPA Convention this past November, perhaps you saw the panel discussion on repairing new propeller designs. Although many popular designs still use a flat-face, the industry has seen a notable increase in new, contemporary propeller designs such as Veem’s Sportfish and Michigan’s Marlin props. These propellers are deliberately designed for high performance and feature unique geometries that manufactured by CNC machining.

If you measure one of these new propellers, you are likely to notice that the local pitch varies across the blade surface. Let’s quickly review some of these variations…

First, let’s review the propeller from the root to the blade tip. On a traditional propeller, we would expect that the section pitch to be the same at all radii – this is referred to as constant pitch. For example, on a 20 inch pitch propeller with constant pitch, the 50R, 70R, and 90R all measure to 20 inches pitch.

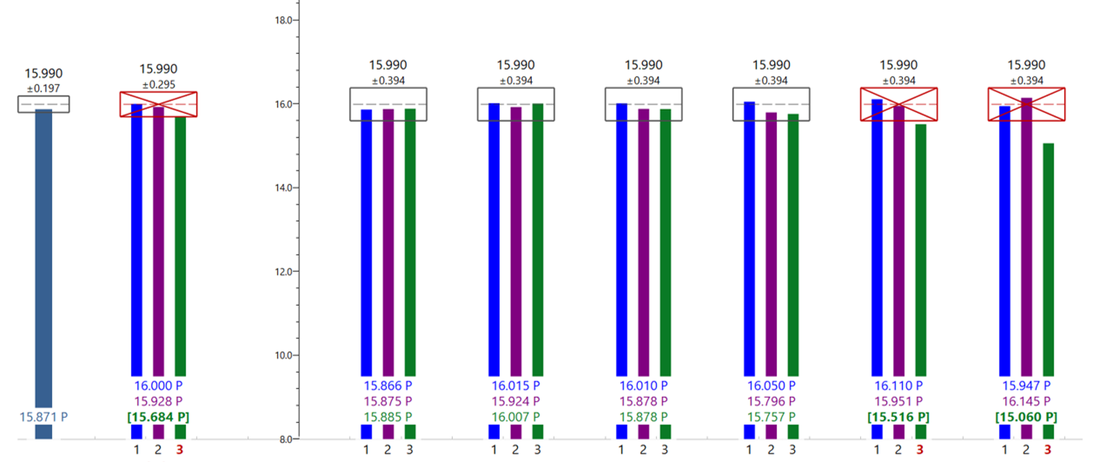

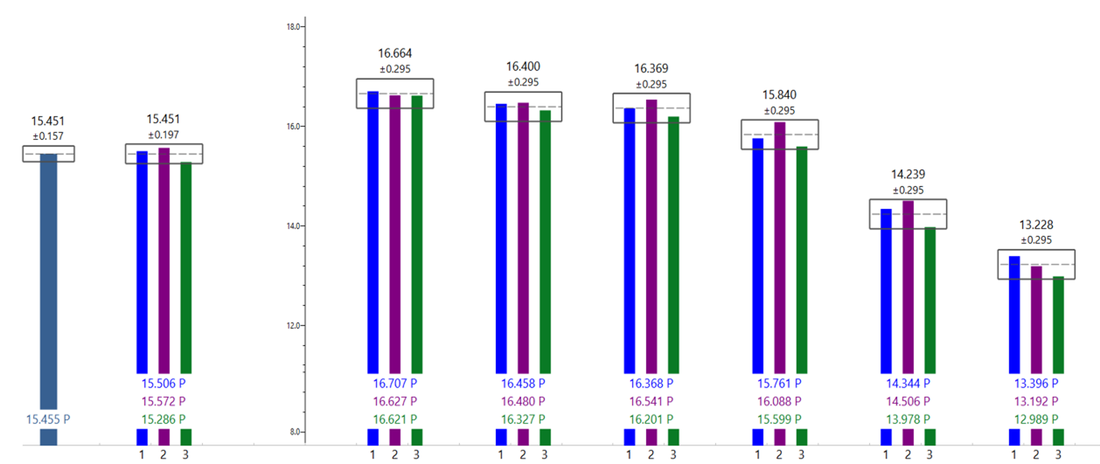

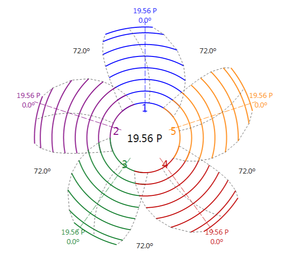

On contemporary propeller designs, the section pitch changes from the root to the tip in order to better match the inflow under the hull – this is referred to as variable pitch. We often see the highest pitch at the 70R, with decreasing pitch at the root and tip. For example, a 20 inch pitch propeller with variable pitch could have a pitch of 19.5 in the 50R, 20.5 at the 70R, and 19.5 at the 90R. The average pitch for the propeller is still 20 inches, but the distribution of section pitch is variable from the root to the tip.

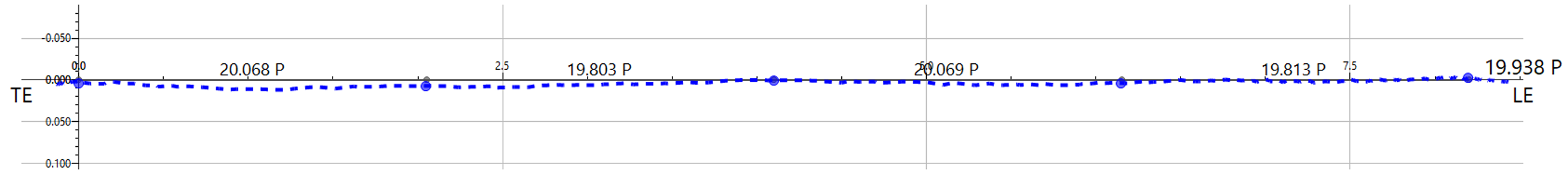

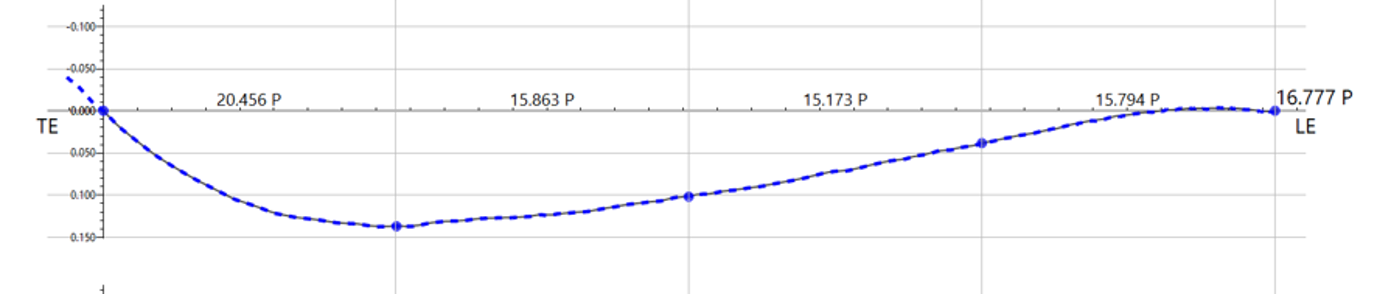

Next, let’s review the propeller from the leading edge to the trailing edge. Again, on many traditional propellers, the propeller face is flat – as a result, the local pitch is the same on the leading edge, the middle, and the trailing edge of the blade. In the previous example of a 20 inch pitch, this means that the first local pitch segment will measure as 20 inches, as will the second and third segments (and so forth). We refer to this as a flat-face/constant pitch foil shape (technically, the term is Ogival).

However, contemporary propellers will have variation in the local pitch from the leading edge to the trailing edge. This is because these propellers utilize camber (additional curvature in the face of the blade) to increase performance. Often, the local pitch increases from the leading edge to the trailing edge – so many people refer to these designs as a cambered-face/progressive pitch.

When repairing propellers, it’s important to review and understand the intent of the propeller’s design. Is the variation in pitch due to damage or was that the design intent? Is this propeller a traditional design, where the face of the blade is flat and the pitch is uniform across all radii? That would be a constant pitch propeller with a flat-face… Is there more to the design? Is this propeller a contemporary design, with section pitch varying from the root to tip, like a variable pitch prop? Is there variation in the local pitch from leading edge to trailing edge, like a cambered faced/progressive pitch propeller? These are important questions to answer before you begin reworking the blades!

We wish everyone a successful 2020 and look forward to seeing all of you at the 2020 convention!

Did you enjoy this article? View PART 2 - Progressive Pitch: Performance at HydroCompInc.com!

We wish everyone a successful 2020 and look forward to seeing all of you at the 2020 convention!

Did you enjoy this article? View PART 2 - Progressive Pitch: Performance at HydroCompInc.com!

| Download the full article... Provided with the permission of the NMPA. |