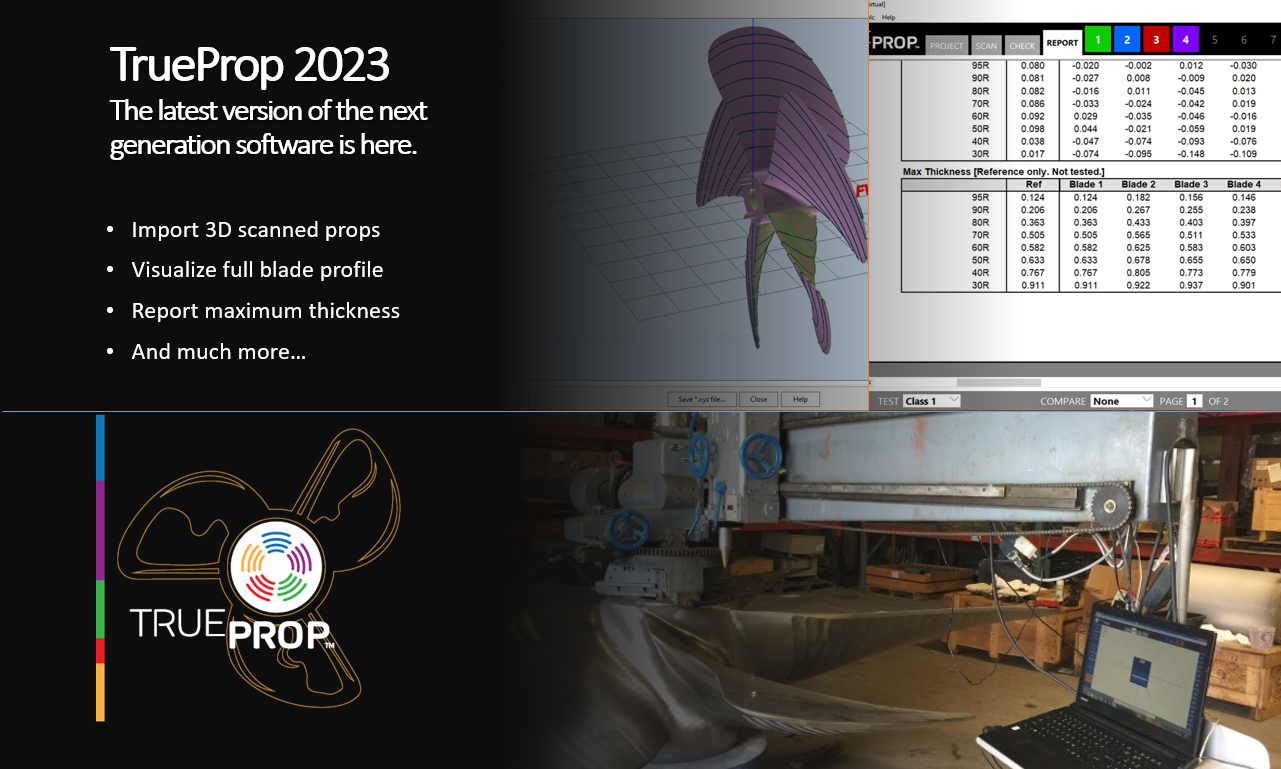

Key Features of TrueProp 2024 Include:

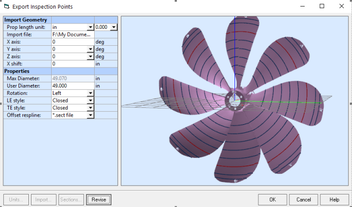

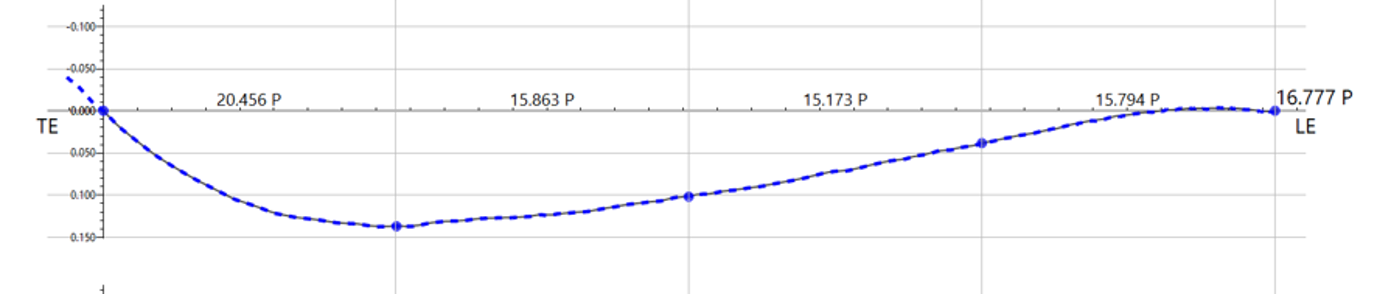

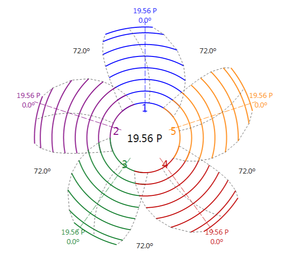

- Blade Rake Utility: Estimate rake angles with precision and ease.

- Job Attachments: Seamlessly add photos and files for comprehensive job management.

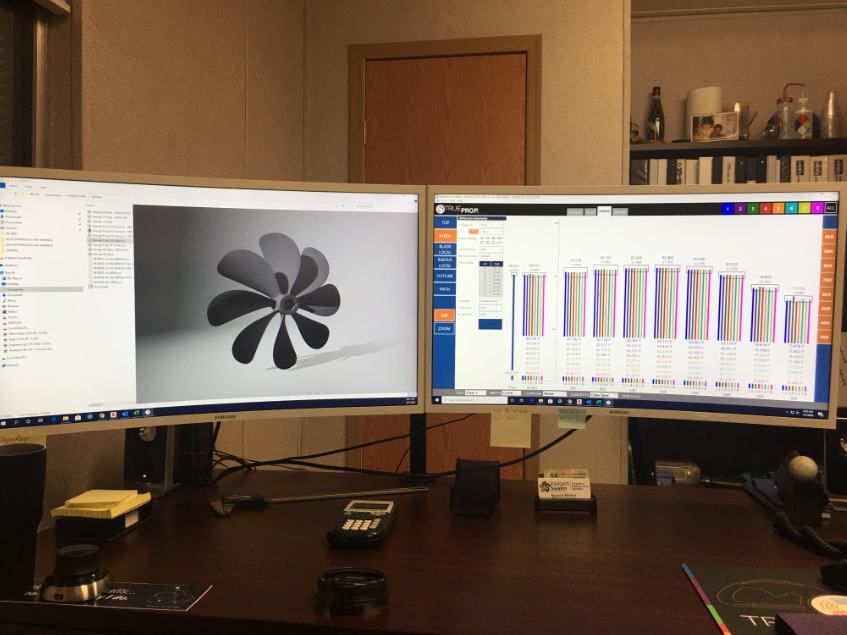

- Enhanced Zoom and Pan Functions: Navigate Rake & Outline plots effortlessly.

- Expanded Keyboard Shortcuts: Streamline operations with additional shortcuts.

- International Support: Operate TrueProp in non-English environments seamlessly.

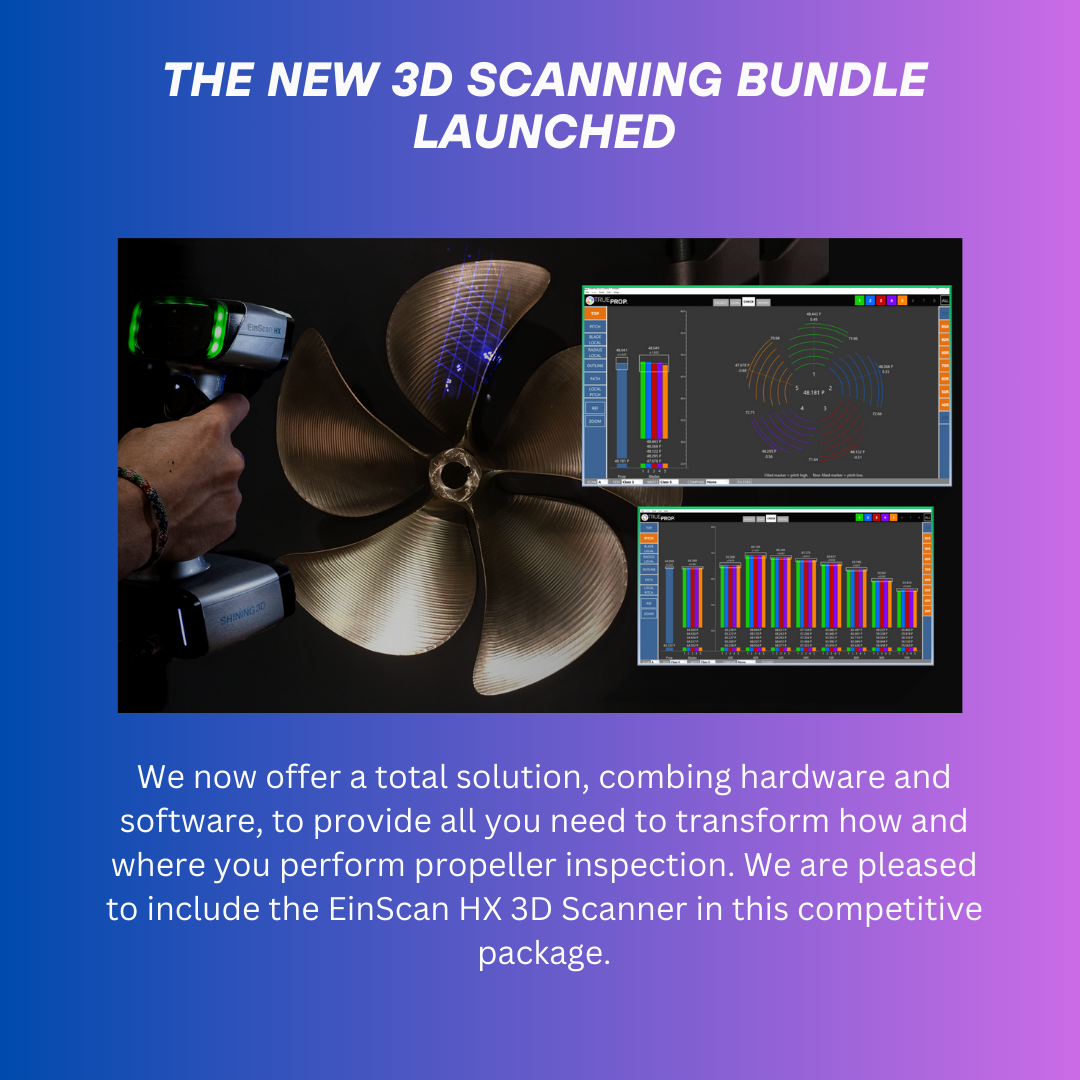

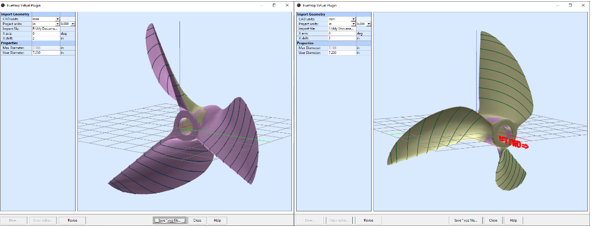

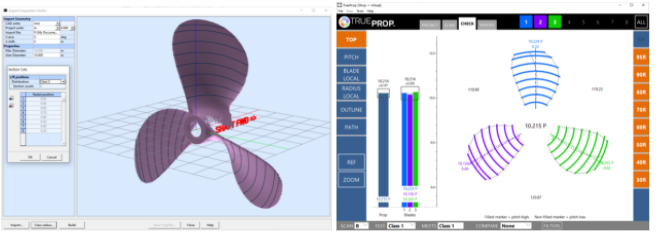

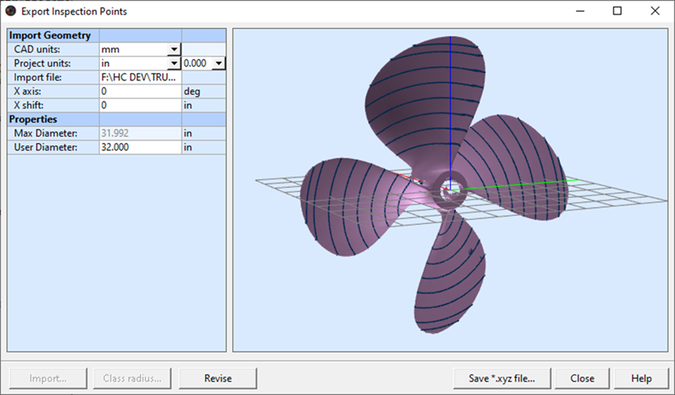

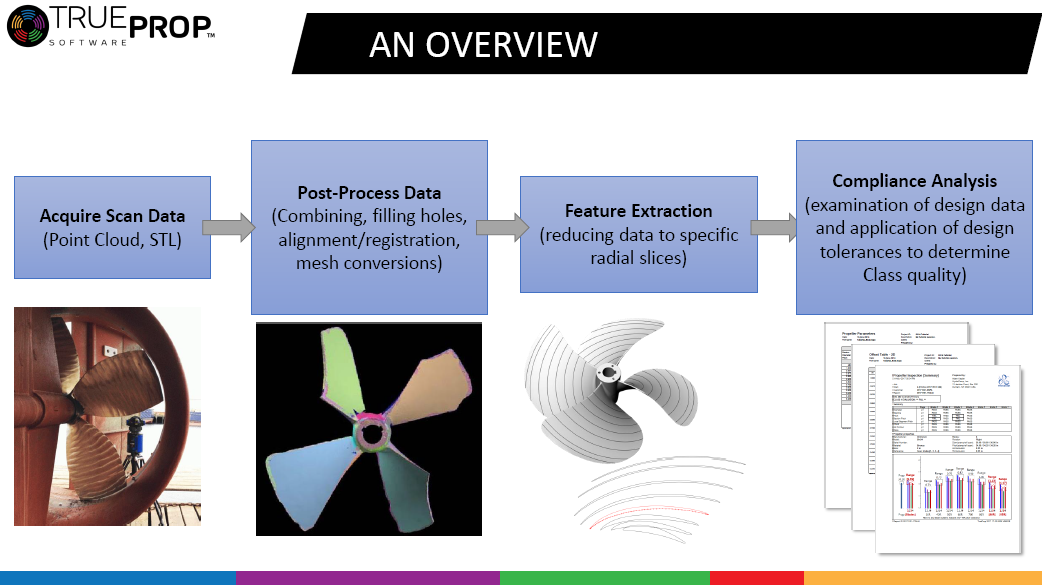

- Direct Virtual Plugin Launch: Post-process 3D scan files directly from TrueProp.

- Improved Guidance: Enhanced colors for easier rescan procedures.

The TrueProp 2024 upgrade is available through our Upgrade and Support program. Contact us today to upgrade your software version or explore additional technical support options, ensuring uninterrupted access to updates and personalized customer service. TrueProp Software remains committed to delivering cutting-edge solutions that redefine propeller inspection software. Join our community of TrueProp 2024 users and experience unparalleled efficiency and support.